RUSTON GAS TURBINE TB5000 ENGINE DESCRIPTION

RUSTON GAS TURBINE TB5000 ENGINE DESCRIPTION

The design of the engine is fully

described in Reference 1, the following is a

brief summary.

The general layout of the engine is shown

in Figure 1. The core comprises of three

major modules: a single spool 10 stage axial

compressor, a two stage turbine and a com-

bustion system made up of six reverse flow

combustors canted and housed in a pressure

casing between the compressor and turbine

modules.

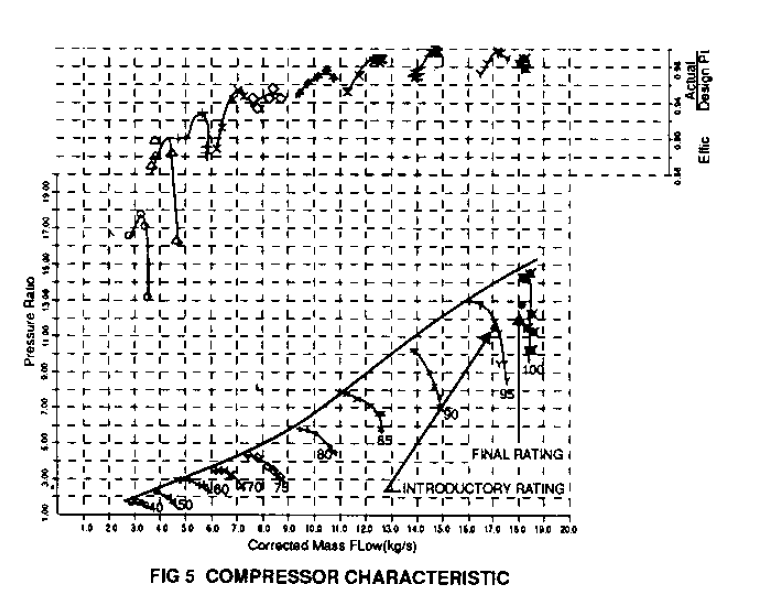

The compressor utilises 10 stages to

achieve the design pressure ratio of 14:1,

although at the current engine rating the

pressure ratio is 12.8:1. The first two stages

are transonic with a maximum tip Mach Number

of 1.1. The compressor, as shown in Figure 2,

is characterised by large chord blades which

allow aerodynamically thin sections to be used

while still maintaining adequate strength for

service durability. The first three stators

and the Inlet Guide Vane are made variable for

surge control at part speed and ultimately for

twin shaft operation.

The turbine is of two stage design,

comprising a High Pressure (HP) and Low

Pressure (LP) stages. The HP stage produces

the power required to drive the compressor,

while the LP stage produces the output power.

Both stages are of transonic design with all

the blade rows having a subsonic inlet and a

supersonic exit. The HP stage blading is

investment cast in IN939 and coated with

Sermaloy J for additional corrosion and oxidation resistance. Both blades are cooled

with air supplied internally from the com-

pressor, to reduce metal temperatures below

900° C on the stator and 800 ° C on the rotor.

The LP stage does not require cooling due to

the high temperature drop achieved across the

HP stage.

The compressor spool, which runs in two

Tilt Pad Journals, is made up of separate

discs and shafts held together via a single

central tension bolt. Location of discs and

shafts is via full ring Birth Couplings at the

outside diameter. The two turbine wheels

which are overhung relative to the compressor

spool, are also held via a central tension

stud and centralised via Birth couplings.

The drive is taken via a high speed shaft

from the end of the turbine. An epicyclic

gearbox reduces the speed from 16500 rpm to

1500 or 1800 rpm. The main lubricating pump is

mechanically driven via the gearbox. The

engine is started via a Hydro Start System,

comprising : an AC electric motor powering a

hydraulic pump and motor system, which is

engaged to the gearbox and engine via an SS

clutch.

The lubricating tank and associated system

is all housed at the cold end of the engine,

as shown in Figure 3, while the gas and liquid

fuel systems are housed immediately below the

engine for rapid response. The control system used is based on the

latest micro-processor technology and is used

on all Ruston products. It provides a fully

integrated package capable of governing,

temperature monitoring, annunciation, fault

monitoring, starting and stopping sequence

control. The power of the system also allows

options for process control, sequencing and

monitoring driven equipment. Facilities are

also provided to extend the system to cover

data logging, plant supervisory control and

financial management of complex power systems.

Comments

Post a Comment