RUSTON GAS TURBINE TB5000 TB5400 ENGINE PERFORMANCE

ENGINE PERFORMANCE

Table 1 shows the measured engine

performance relative to design intent. The

observations from these early tests showed

that the thermal efficiency of the engine was

slightly down with the knock on effect that

the firing temperature required to achieve the

power is increased. This deficiency was

traced to the turbine which appeared not to be

performing to the same level of performance as

seen on the model turbine test presented in

Reference 2. A strip of the turbine revealed

that the HP turbine tip clearance seal had not

cut into the honeycomb seal. The tip

clearance on both the HP and LP turbines is

controlled via a low expansion carrier ring

and therefore both stages were expected to

behave in a similar manner. Detailed tip

clearance measurements on the LP stage showed

the turbine to be running with approximately

0.5 mm excessive clearance.

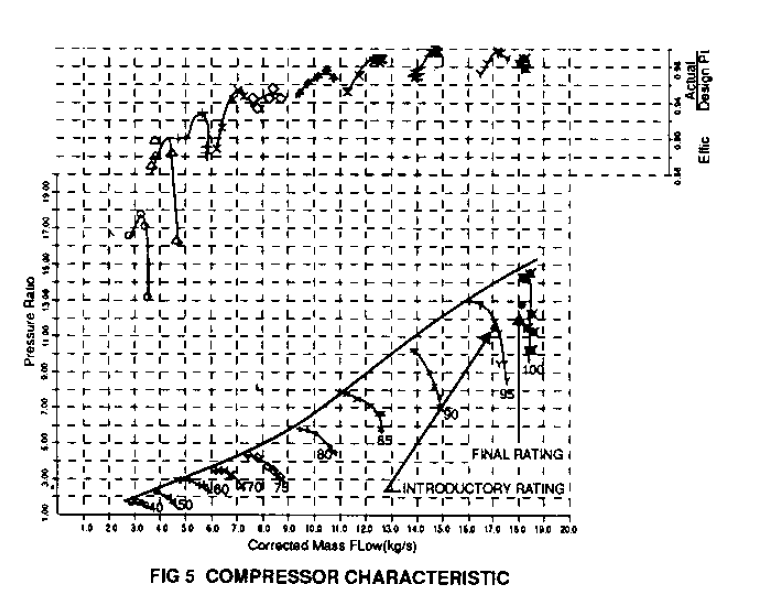

In a similar manner the high pressure end

of the compressor was observed to be running

with tight clearances and these were opened up

.1 mm.

With the above clearance adjustments the

engine performance was re-established and

shown to be close to prediction in terms of

all major parameters including firing

temperature and thermal efficiency. Further

work to reduce leakage paths within the

turbine area resulted in all the design

targets being met or exceeded.

Comments

Post a Comment